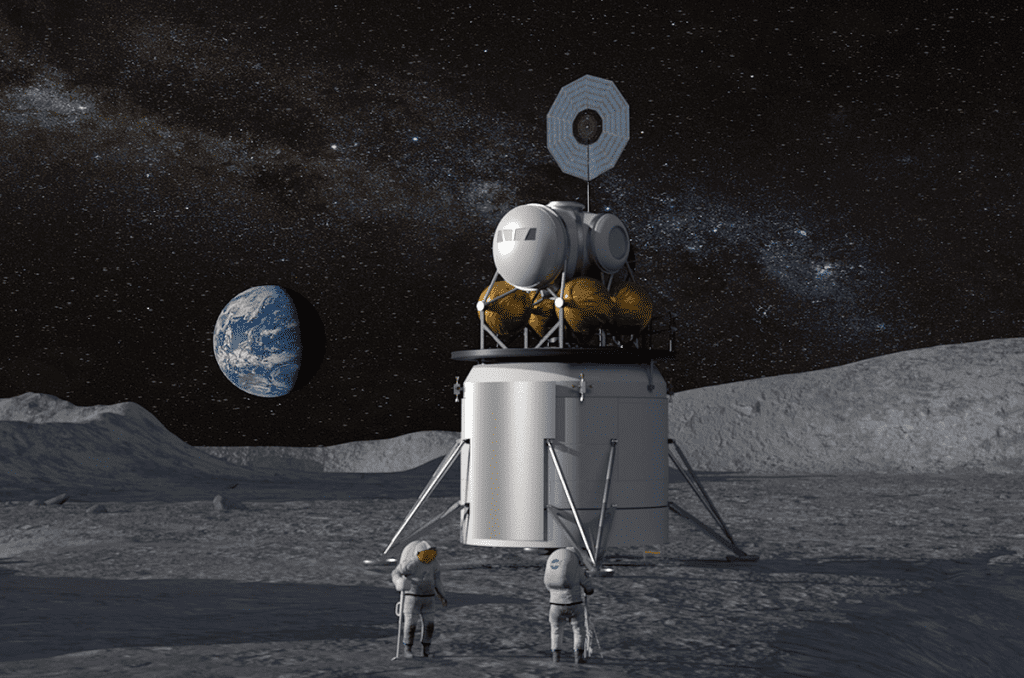

Although humans haven’t returned to the Moon in their bodies just yet, business is booming in the Moon economy. For instance, according to Axios, a 3D printing company called ICON, based in Austin, Texas has just received a $57.2 million cash infusion from NASA for its Project Olympus, an ambitious effort to develop 3D-printed lunar shelters.

Watch Video

If the Artemis mission timeline holds, as reported by Axios, ICON hopes to have its Moon huts ready for NASA use by 2026. ICON’s chief executive officer, Jason Ballard, appears to be taking seriously the idea that resilient yet lightweight lunar housing is crucial if the Moon is to become a human outpost.

“We feel real weight and responsibility — we’re not just doing this for ourselves,” Ballard told Axios, adding that “we’re giving humanity the capability to build on other worlds.”

He went on to say that the completion of the contract would mark “the final deliverable of this contract: humanity’s first construction on another world,” calling it “a pretty special achievement.”

Cosmic Contractors

Although ICON is best known for its terrestrial construction projects, the company has long harbored aspirations to expand into the space realm. Launching in 2020, Project Olympus appears to have as its ultimate goal the establishment of a 3D-printed Mars colony.

Moondust, shattered rocks, and other naturally occurring lunar components will be used to construct the lunar homes; ICON’s plan is to avoid littering the Moon’s relatively clean surface with a bunch of Earthly junk.

In Ballard’s view, human settlements on the Moon can only last as long as humans can figure out how to make use of the regolith that already exists there. (After all, if Moon miners needed to receive a payload from Earth every time they needed to build a new road, that would be a royal pain in the rear.)

According to Ballard’s estimates, “if you tried to plan a lunar settlement or a moon base and you had to bring everything with you, every time you wanted to build a new thing it’s like another $100M,” which would make the total cost of the project prohibitive.

To put it another way, “once you’ve got a system that can build almost anything — landing pads, roadways, habitats — and it uses local material, you are probably two or three orders of magnitude cheaper to build a permanent lunar presence than you would be in any other way that we can think of.”