With this staggering sum, the Biden Administration has shown its commitment to domesticating the electric vehicle supply chain by agreeing to loan a Nevada startup $2 billion to support its production of critical battery materials.

With this funding, Redwood Materials will build the very first factory in the United States to manufacture anode copper foil and cathode active materials, two critical parts of electric vehicle batteries. The company, started by a former Tesla executive named JB Straubel, claims it can produce enough of them to allow for the annual production of 1 million electric vehicles by 2025.

The Department of Energy estimates that this would result in an annual savings of over 395 million gallons of gasoline and a reduction of over 3.5 million tons of carbon dioxide emissions. It would also lessen the need for automakers to import battery components from other countries.

On Friday, Bob Marcum, chief operating officer of the DOE Loan Programs Office, told Grist that the project would achieve the goals of reducing greenhouse gas emissions by decreasing reliance on critical minerals from Asia, bringing manufacturing and the supply chain to the US, and producing components for electric vehicles. “It’s a huge undertaking, and we couldn’t be more thrilled about it.”

The loan will come from the Advanced Technology Vehicles Manufacturing Loan Program, which provides funding for manufacturing projects with the goal of increasing vehicle fuel efficiency. The conditional commitment was announced on Thursday by the Energy Department.

In 2030, the Biden administration hopes that electric vehicles will account for 50 percent of all new vehicle sales. Electric vehicle batteries’ core components are almost entirely manufactured in Asia.

Energy Secretary Jennifer Granholm said at a Thursday event at Redwood Materials’ Nevada facility, “We have some catching up to do.” Every link in the supply chain can trace its origins back to China. This increases the cost of batteries, creates greenhouse gas emissions from shipping them around the world, and endangers the safety of the supply chain as a whole.

“Once we realized how systemically important this technology had become to our entire transportation system and our grid, all eyes started sharpening on how to build independence,” explained Nathan Iyer, a senior associate at the clean energy nonprofit RMI.

More than $135 billion from the Bipartisan Infrastructure Law, the CHIPS & Science Act, and the Inflation Reduction Act goes towards the electric vehicle transition in the United States, including the procurement of essential minerals and the production of batteries.

Iyer remarked, “They targeted basically every part of the manufacturing process.” That the United States is acting in such a novel, strategic, and aggressive manner is an understatement.

In 2017, JB Straubel, a former CTO at Tesla and co-founder of Redwood Materials set up shop. During his time at Tesla’s huge Nevada Gigafactory, he came to the conclusion that the US would soon have a hard time getting the materials it needs for the EV transition. “Even eight years ago, it was clear this would be a really big bottleneck for the entire industry as it scaled,” he said at the Thursday event.

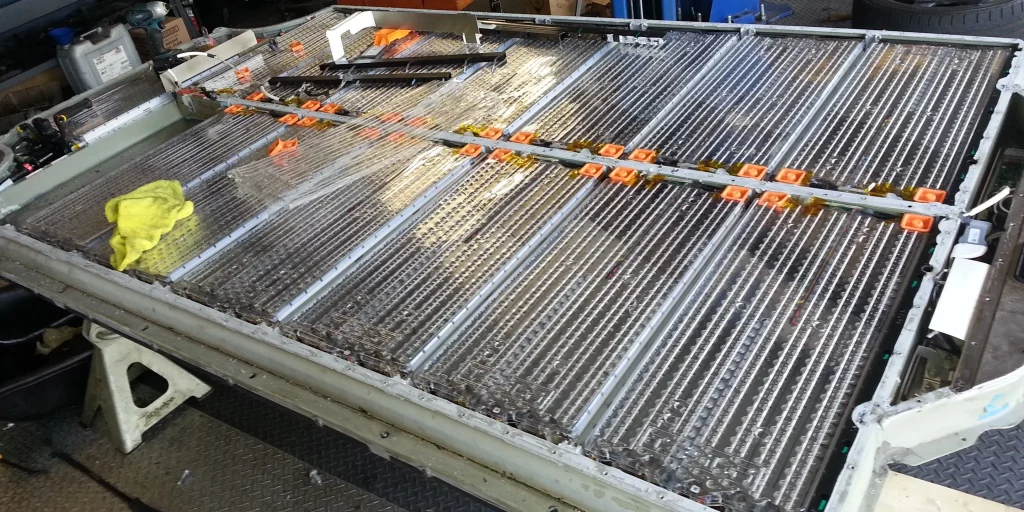

For electric vehicles, Redwood Materials will manufacture both the anode, which aids in charging performance and the cathode, which houses the battery’s critical metals. They account for nearly 80% of the total price of a battery. As well as ensuring a steady supply of raw materials, making them at home can lower the price of batteries, making electric vehicles more accessible to the general public.

A month ago, Redwood Materials launched commercial production of anode copper foil at its Nevada facility, marking the first time this component has been manufactured in the United States. The company anticipates starting cathode product testing by the end of the year.

When fully operational, the Nevada facility will provide full-time employment for around 1,600 people.

The business is instituting a more sustainable battery supply chain. Redwood Materials has begun recycling the metals used in EV batteries by collecting scrap from factories, lithium-ion batteries from e-bikes, consumer electronics, and other sources, and then using them in the anode and cathode components of its batteries.

However, the infrastructure Redwood Materials is developing now could one day support nearly completely closed-loop battery manufacturing when there are enough electric vehicle batteries in circulation to use materials exclusively from recycled sources.

Iyer noted that while the company is “a little ahead of the recycled material inputs,” “if they are successful, this will be the cornerstone of the circular economy.”

Secretary Granholm says that in the last two years, 80 companies that make or sell batteries or are part of the supply chain have said they will move to or open in the United States. She said that the current situation was caused by the development of an industrial strategy to make these goods in the United States. Is China getting nervous?